By the wording ‘solid’, it may imply to us that the propellant composition is in some sort of hardened state. In the old days (but still around today) black powder, a mechanical mix consisting of potassium nitrate (KNO3), sulfur (S) and charcoal (C) would either be compressed mechanically or by adding rubber arabicum (natural rubber) to solidify the otherwise powdery state of the ingredients. Both methods were essential for a good functioning of a rocket in order to ensure smooth combustion with time whereas a propellant in just powdered state would more likely lead to unpredictable burning with the increased risk of motor rupture (explosion). A picture of black powder mixture is shown in Figure 1.

A good balanced mixture for rocket use when using black powder is given in the following table.

| Ingredient | Function | Formula | % per mass |

|---|---|---|---|

| Potassium Nitrate | Oxidizer | KNO3 | 75 |

| Sulfur | Fuel | S | 10 |

| Carbon | Fuel | C | 15 |

When black powder burns, it does this with a high temperature flame producing huge amount of smoke and solid products. The chemical reaction (simplified) of burning black powder is given below:

10KNO3(s) + 8C(s) + 3S(s) → 2K2CO3(s) + 4K2SO4(s) + 6CO2(g) + 5N2(g)

Some characteristics are listed in the following table.

| Black Powder | Value |

|---|---|

| Specific impulse | 830 m/s |

| Reaction temperature | 3070 K |

| Solid products | 56 % |

| Gaseous products | 43 % |

| Water | 1 % |

Black powder is still in use as a rocket propellant, but it is only found in fireworks and model rocket motors. Black powder may occasionally be used for igniting solid propellant rocket motors. Due to its low specific impulse, hygroscopic and powdery nature, the propellant has long since been replaced by far more energetic, mechanical strong and stable compounds.

Modern solid propellants consist of ingredients that are in a solid and liquid state during the mixing process. All solids are typically based on an oxygen rich salt like ammonium perchlorate (NH4ClO4) as the oxidizer and aluminum powder (Al) as fuel. Ammonium perchlorate contains 54.5 % per weight oxygen. The liquid part is often an industrial long chain polymer. The purpose of the polymer is to harden and thereby fixate the powered based part of the mix. A commonly used polymer is Hydroxyl-Terminated PolyButadiene or HTPB (CxHyOz). The hardening process is triggered by adding a hardener agent like Isoforon diisocyanat (C12H18N2O2) in order to start the cross-polymerization process.

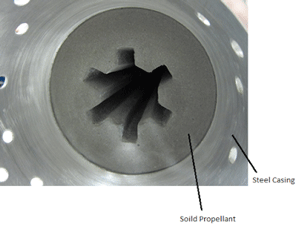

After mixing the propellant typically has a viscous state. The mixture is then poured by gravity or by pressure over to the rocket chamber where a casting mandrel is placed in the center of the engine.

The geometry of the mandrel will vary from program to program. Often it can have a star shape. When the propellant has filled the allowable volume, the motor will be transported to a curing oven. Typically, the mix will be allowed cure for a weekly long period at an elevated temperature (60–70 °C). When cured, the propellant grain can be compared to the sensation of touching an ink rubber. A modern composite propellant charge can contain eighteen different ingredients. The main important ones are the molecule holding the oxygen (oxygen rich salt) and a fuel, e.g. aluminum, beryllium or the fuel binder itself. Other minor per mass ingredients are additives for chemical stability, pot life plasticizer, burn rate catalysts, anti-softening, curing additives, and more.

Example of a modern composite solid propellant mixture:

| Ingredient | Function | Formula | % per mass |

|---|---|---|---|

| Ammonium Perchlorate | Oxidizer | NH4ClO4 | 68 |

| Aluminum | Fuel | Al | 20 |

| HTPB | Fuel-binder | CxHyOz | 11.5 |

| Isoforon diisocyanat | Curative | C12H18N2O2 | 0.5 |

A modern composite propellant can give 2500 m/s (255 s) specific impulse. This is almost three times more efficient than the old black powder. Composite propellants are used in everything from small tactical rocket motors for missiles to the big and very powerful solid rocket boosters for launch vehicles.

To balance the amount of oxygen with the amount of fuel is important in rocketry. In chemistry we know that a stoichiometric reaction is a complete chemical reaction between the amounts of reactants (oxidizer + fuel) and products. This is not always practical possible or wanted based on performance. As an example: in solid propellant mixtures you may find that theoretically you should have above 88 % oxidizer concentration in your mix, since this will give you higher performance (specific impulse). That can sometimes be difficult to achieve since you may have other requirements on your propellant like mechanical strength and chemical bonding properties. In modern solid propellant mixes we have to assess the balance of three major parts, the amount of oxidizer, the amount of fuel and the amount of binder.

All solid propellants are potentially dangerous mixtures. This is so since they contain oxidizer and fuel already mixed together. The composition may be fairly robust but still it may just need a spark to start the combustion. As soon as the composition has started to burn, it will be very difficult or impractical to stop it. Water will not help.

Depending on the chemical composition used, a solid propellant can burn slowly — or not at all — at ambient pressure. However, if you ignite the same propellant in a confined volume, you may get the opposite result: a quick reaction. Most solid propellants burn at higher rates at higher pressures.

Sometimes a rocket engineer wants to increase the propellant burn rate without increasing the pressure so much. For such cases we often add in iron oxides (e.g. Fe2O3) in amounts of 0.5–3.0 % all depending on the chemicals used and the needs required. For such cases iron oxides behaves as a burn rate catalyst.

<< Previous page – Content – Next page >>

This article is part of a pre-course program used by Andøya Space Education in Fly a Rocket! and similar programs.